Phone No

020-25887143

Dimple Chemicals & Services Pvt. Ltd. is the manufacturer of surface preparation products, surfactants & performance chemicals products for the last 30 years. We are a pioneer in the field and are known for patented surface preparation products and technologies. We have an array of surface protection products for both metal and concrete applications. Our in-house R & D facility and a well-equipped quality control laboratory help us in meeting the stringent demands of customers from a wide spectrum of industries. We are headquartered at Pune, which comprises a state-of-the-art facility spread over 60,000 square feet. The company’s current production capacity is 10,000 TPA, a value achieved with a motivated workforce. Our wide range of superior quality products can meet the stringent demands of a spectrum of industries such as infrastructure, construction railway, engineering, hydel projects, chemical, ports, paint industries etc. Our client list includes some of the biggest names such as Dalmia Cement, ATE Enterprises, Godrej Agrovet Ltd, Adani Power Ltd., Tata Power Ltd, Grasim Industries, Hindalco Ltd, KLT Automotives Ltd. to name a few.

Our motivated team uses in-depth technological skills to consistently deliver for our customers by setting benchmarks in quality products, innovation and knowledge. Over the years we have developed and added innovative ‘DuraClean’ and ‘‘DuraGuard' for corrosion control & protection of metal surfaces. These technologies are energy-efficient and environment-friendly. During the last decade, it has been deployed with excellent results for varied applications.

Product Range 1 - Steripure 10, DuraClean OD and DuraClean WR for Surface Preparation

We have a range of Surface Preparation products, namely, Steripure 10 (to remove nanoparticles & dirt), DuraClean OD (to emulsify oil & grease) and DuraClean WR (to reduce unwanted substrate/oxide) are used for surface preparation.

Steripure 10: The growth of algae-fungi on a humid surface is a common problem. Steripure 10 is an antibacterial, antifungal water base solution to remove algae-fungi from the surface by killing roots. This also cleans nanoparticles, dirt/ducts from the surface.

DuraClean OD: This is an organic polymer for emulsification & dispersion of oil and grease spilled on the surface. This emulsified oil/grease can be easily removed by water wash. De-oiled & de-greased surface is a primary requirement for any process or application.

DuraClean WR: This is an organic polymer for the conversion of an unwanted substrate (burr) on the metal surface by crystal structure modification into docile form. Growth of oxide is in mathematical progression hence burr on the surface is to be as low as possible. This method of surface preparation brings burr on a surface below 25 microns. This product improves the surface texture. It is also anti-static and biodegradable. DuraClean WR also controls embedded, Bio & bi-metallic corrosion.

Application areas

Product 2- DuraGuard for surface preparation

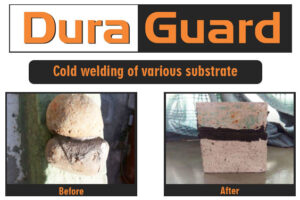

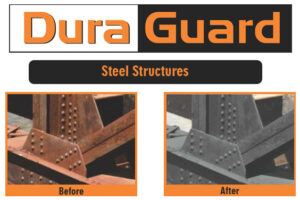

DuraGuard is a unique combination of organic and inorganic materials consisting of Ceramic Ironite, Active ceramic, cement & water-miscible modified epoxy. This is a dot matrix coating hence gives strong adhesion with any substrates like metal, concrete, wood, PVC and any other substrate. The product gives better resistance against corrosion and abrasion with added UV and impact resistance. It is no-toxic in nature with high breakdown voltage, high electrochemical impedance, thermal resistance and ant-rodent properties. DuraGuard also has an innovative ‘cold welding property which helps to form a strong bond between dissimilar materials like metals, glass, plastic, wood, ceramic materials etc.

Application areas of ‘DuraGuard’

020-25887143

info@dimplechem.com

http://www.dimplechem.com/